Large-scale production of green hydrogen from sustainable sources such as sun and wind still requires the removal of technological barriers. Electrolysis, a method of splitting water into hydrogen and oxygen, is needed to store and transport large amounts of wind energy to industry and for heavy transport. It’s happening on a small scale now. In Europe’s largest Hydrogen Research Facility, Faraday laboratorium, TNO is working on technological breakthroughs to scale this up.

Faraday innovation center: Europe’s largest hydrogen research facility, see impression here: TNO Faraday Hydrogen Research lab – YouTubeThere are currently several barriers to large-scale sustainable hydrogen production. The electrolysers needed for this are still too expensive to compete with the cheap fossil natural gas that is now used to produce hydrogen. For example, the PEM (Proton Exchange Membrane) contains electrolyser parts made of rare, expensive materials such as iridium and platinum. Not only is the number of component suppliers limited but so is the cooperation between parties in the chain. Finally, a sharp rise in the share of sustainably generated electricity is still needed if we want to produce green hydrogen on a large scale.

Sustainability offers opportunities

TNO will be significantly expanding the Faraday lab in Petten in the coming period with facilities to work on innovative solutions together with industrial partners. Electrolysis is not only an indispensable link in making our energy supply more sustainable, it also offers enormous opportunities for the Dutch, European and the global industry. The market is expected to grow from one hundred million to five billion euros in northwest Europe over the next decade. Together with suppliers, we develop efficient systems with sustainably designed components and cheaper materials.

Partners at home and abroad

Getting the production of sustainable hydrogen up to an industrial level requires an increase in scale by a factor of one thousand. To achieve this, TNO is working with national and international partners in the project to design a ‘Gigawatt Electrolysis Factory’. Heat and oxygen can be valuable by-products of electrolysis. The Faraday lab also exchanges knowledge with the Hydrohub in Groningen, where TNO, together with other knowledge institutes and companies, is investigating the large-scale sustainable production of hydrogen through water electrolysis. Here, too, rapid upscaling of the technology is the starting point.

Open innovation

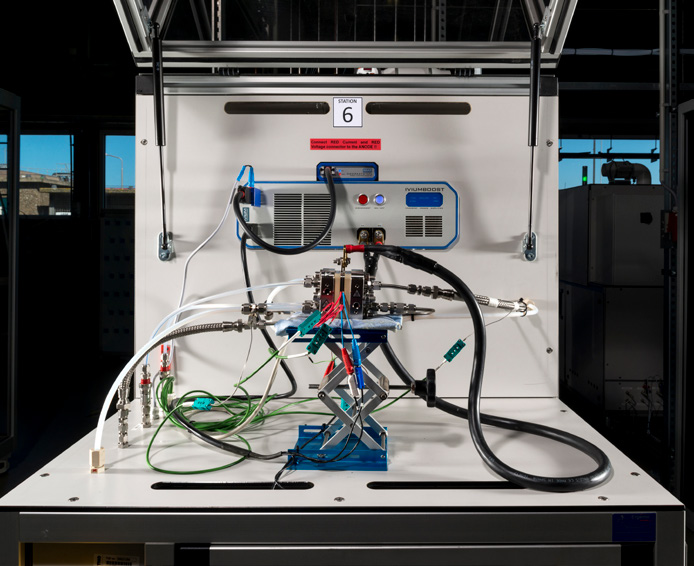

Faraday is an open innovation lab that focuses on optimising existing electrolysis technologies such as PEM, alkaline, SOEC and AEM. The future electrolysers must work more efficiently, produce more, comprise cheaper materials and are therefore be attractive to use. TNO works together with manufacturers of electrolysers and their suppliers. Manufacturers can develop and test new materials, components and applications with TNO under different conditions. All the necessary facilities are available in the lab. Dutch industry can lead the way here and through innovative products be distinctive players in the world market.

Lennart Vanderburg

Hydrogen expert and as cluster manager green hydrogen responsible for the green hydrogen R&D development program within the leading Dutch applied research centre TNO